Silver Brazing

is a precision joining process offered at Subbaiah Enterprises, widely used in the fabrication of high-strength, leak-proof, and corrosion-resistant joints. This technique is especially suitable for joining dissimilar metals or components that cannot tolerate the high temperatures of welding.

What is Silver Brazing?

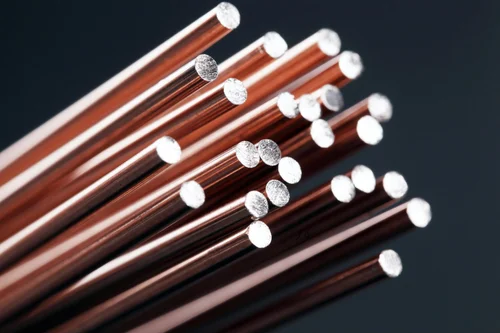

Silver brazing involves the use of a silver-based filler metal, which has a lower melting point than the base materials being joined. The filler metal is melted and distributed by capillary action between closely-fitted metal surfaces, forming a strong metallurgical bond without melting the base components.

- Typical brazing temperatures: 600°C to 850°C

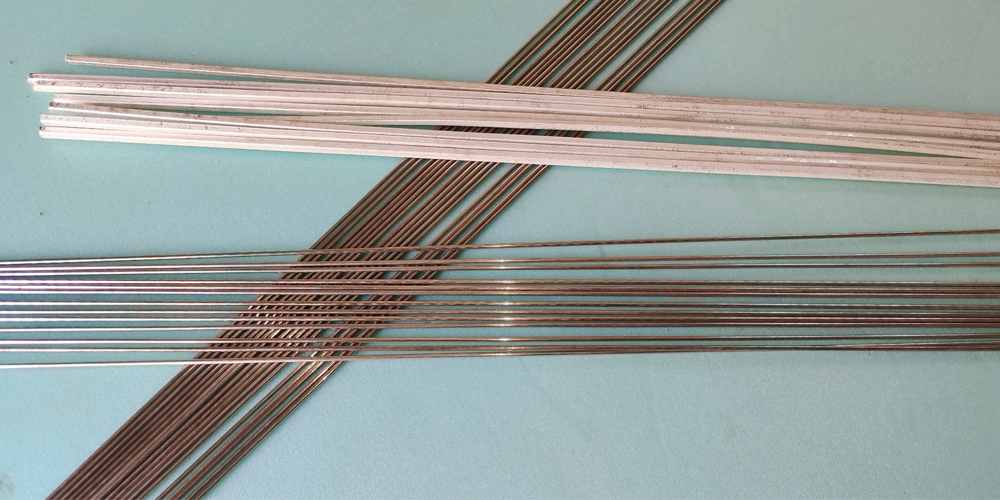

- Common filler alloys: Silver-copper-zinc, Silver-copper-phosphorus, Silver-nickel

- Atmospheres used: Open flame, flux-assisted, or inert environments

Advantages of Silver Brazing

- Joins Dissimilar Metals: Effective on copper, brass, steel, stainless steel, and carbide.

- No Distortion or Warping: Base metals retain their mechanical and dimensional integrity.

- Strong, Durable Joints: High tensile and shear strength with excellent fatigue resistance.

- Leak-Proof Sealing: Ideal for pressure-tight and fluid-handling applications.

- Precision and Clean Finish: Minimal post-process machining or cleaning required.

Applications of Silver Brazing

Subbaiah Enterprises serves a wide range of sectors with silver brazed assemblies, including:

- Carbide tool tips and cutting edges

- Heat exchangers and condensers

- Electrical connectors and terminals

- Instrumentation and sensor housings

- Hydraulic and pneumatic fittings

- Assemblies in aerospace, automotive, and energy equipment

Our Brazing Capabilities

- Oxy-Acetylene and Induction Brazing Stations for controlled, localized heating

- Precision Fixturing to maintain tight tolerances during assembly

- High-Purity Brazing Alloys selected for compatibility and performance

- Flux Selection and Application Expertise to prevent oxidation and ensure bond strength

- Post-Braze Inspection including dye penetrant testing, visual checks, and pull tests as needed